What is industrial IoT or IIOT?

The phrase "industrial internet of things," or IIoT, refers to using intelligent sensors and actuators in manufacturing and other industrial processes to increase efficiency. IoT (or Industry 4.0) is a concept that uses "smart machines" as well as real-time analytics to make use of the data that "dumb machines" have been creating in industrial settings for an extended period. IIoT's underlying principle is that intelligent robots are better for people in real-time data collection and analysis and in transmitting critical information that can be utilized to drive business choices more promptly and accurately.

Using sensors and actuators connected to the Internet enables organizations to uncover inefficiencies and difficulties more rapidly, saving time and money and supporting their efforts to increase business intelligence and business agility. The IIoT has enormous potential for quality control, sustainable and environmentally friendly practices, overall supply chain efficiency and supply chain traceability in the industrial business. Activities like improved field service, energy management, prescriptive maintenance, and asset monitoring are all dependent on the Industrial Internet of Things.

How does the Internet of Things (IIoT) work?

The Industrial Internet of Things (IIoT) is a network of interconnected intelligent devices that can collect, distribute, and analyze data to build more extensive systems. Industrial IoT ecosystems are made up of the following components:

- Networks of devices can see their surroundings, communicate with one another, and retain data about themselves.

- Public or private data transmission network infrastructure.

- Raw data analytics and programmes that generate business information

- Equipment and people linked to the Internet of Things generate data, which is stored in the cloud.

They deliver data directly to the data communications infrastructure, where it is turned into information that may aid in making choices about the functioning of a given piece of machinery. This information has two potential uses: predictive maintenance and operational optimization.

The Internet of Things (IoT) infrastructure consists of the edge gateway, edge nodes, edge sensors, and edge actuators. It also includes the edge sensors and the edge actuators themselves.

In what industries is IIoT being used?

Today, the Internet of Things (IIoT) is employed in many industries. Because of the use of IIoT-connected devices in the manufacturing process, the automotive industry serves as an excellent case study. Industrial robots are used extensively in the automotive industry, and IIoT may help identify potential difficulties before they have a negative impact on output.

In addition, the agriculture industry makes extensive use of the IIoT devices that are already available. Agricultural sensors collect data on soil nutrients and moisture levels, among other factors, allowing farmers to create an ideal crop.

What are the benefits of the Internet of Things?

IIoT devices in the industrial sector are often recognized for their potential to do predictive maintenance. A firm may utilize the real-time data generated by IIoT devices to develop precise projections of equipment maintenance requirements, such as frequency and type. This strategy allows routine maintenance to be performed before a breakdown. This may be a lifesaver on a manufacturing line where a piece of malfunctioning equipment can cause a halt to output and huge losses. If an organization takes proactive efforts to address maintenance issues, it has the potential to increase its operational efficiency.

Another benefit is that field service is more efficient. The Internet of Things (IoT) enables field service technicians to identify potential problems in client equipment before they become significant issues. Using this method, field service personnel can fix the problems before they harm customers. In the future, these technologies may also provide field service technicians with information on the parts they require to perform a repair. On a service call, experts will already have all the necessary parts.

Another benefit of IIoT is the ability to track assets. Asset management systems allow consumers, manufacturers, and suppliers to track the location, status, and condition of things across the supply chain. The system will provide rapid alerts to the appropriate stakeholders if any of the artefacts are damaged or at risk of being destroyed. They may then take immediate or preventive action, if necessary, to correct the situation.

The Internet of Things (IIoT) also enables businesses to create a better consumer experience. Manufacturers may use the Internet of Things to collect and analyze data on how customers use their goods. A more customer-centric approach allows manufacturers and designers to build product roadmaps.

The IIoT also makes facilities management more efficient. Wear and tear might be exacerbated by the conditions under which the equipment is utilized in production (namely, the factory). Sensors can keep an eye on things like vibrations, temperature, and more, all of which may lead to less-than-ideal operating conditions.

Is the Internet of Things safe?

The common belief that Internet of Things (IoT) devices are inherently risky stems from the fact that early IoT device manufacturers paid little attention to security while developing their products. Several aspects of IoT and IIoT devices need to determine whether they are safe for industrial use.

As with any other linked equipment, the Industrial Internet of Things (IIoT) has to be evaluated individually. If one manufacturer's product has a high degree of security, another may not. Despite this, electronic equipment manufacturers place a greater emphasis than ever before on security.

The Internet of Things (IIoT) presents several risks and challenges

IoT implementation is riddled with several risks, but data security concerns are by far the most worrisome. It is fairly unusual for Internet of Things (IoT) devices to continue using the passwords that were established for them by the manufacturer after they have been placed into production. Like many devices in the Internet of Things (IoT), they exchange data in simple language. Malicious actors would easily intercept the data being received from an IIoT device if these conditions were present. In the same way, an adversary may use an unprotected IIoT device to conduct an assault on other network resources after they have successfully gained control of the device.

It is not only challenging to keep the Internet of Things (IoT) devices secure but also difficult to manage these devices efficiently. A practical approach for managing IIoT devices will become more critical as the number of these devices grows. Businesses need to recognize IIoT devices to prevent their staff from using counterfeit equipment, to be more exact. Identifying each individual device is necessary for tasks like replacing a malfunctioning one or performing a device refresh.

IoT device patch management is yet another big challenge that has to be solved. Firmware updates are becoming a more common practice among electronic device manufacturers. Organizations need a way to check devices to see whether they have the most current firmware loaded and a way to release new firmware if it is required. A tool of this sort must also be maintained in line with the protocols defined by the firm to avoid disrupting business operations.

Where do IoT and IIoT vary most from one another?

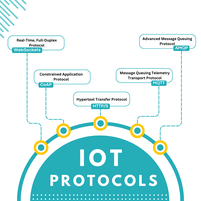

While sensors, cloud platforms, machine-to-machine interactions, connectivity, and data analytics are all present in both the Internet of Things and the Industrial Internet of Things, their applications are considerably different.

A broad range of industries, including healthcare, agriculture, business and consumer use cases, governments, and cities, are connected to the Internet of Things. Even if anything goes wrong with IoT devices like fitness bands, smart appliances, and other apps, they are unlikely to result in life-threatening situations.

Conclusion

The Industrial Internet of Things, on the other hand, connects equipment and devices in industries such as manufacturing, utilities, and oil and gas. Even life-threatening circumstances might be created by system failures and downtimes in IIoT implementations. While IoT applications concentrate on the needs of the end-users, IoT apps for the Industrial Internet of Things are more concerned with boosting productivity and safety.

Explore more

Need any help in IoT?

Need any help in IoT? An Atreyo expert identify the right solution for your needs.

If ready to talk to an Atreyo expert

Interested in IoT products? go to